Dissertation | Ph.D.Engg.

Computational Modeling and Experimental Validation of Advanced Electrostatic and Magnetic Separation Processes for Lunar Regolith Beneficiation toward In-Situ Resource Utilization

Advisor: Dr. F. Rezaei, Professor, Missouri S&T, CEME, UMiami

Abstract:

Lunar regolith beneficiation based on in-situ particles separation face significant challenges due to the unique properties of regolith particles and extreme environments of lunar regions, including high particle heterogeneity, fine dust adhesion, and the complex interplay of their electrical and magnetic properties. Conventional separation techniques often struggle to effectively isolate target minerals of diverse size ranges while simultaneously removing unwanted materials, thereby limiting the potential of efficient in-situ resource utilization (ISRU). To address these challenges, this dissertation investigated and developed an integrated electrostatic-magnetic size separation system that combines computational modeling and experimental validation which is structured around three primary objectives: (1) simulate particle trajectories in an electrostatic sieve to optimize control parameters; (2) model an electrostatic system to achieve efficient particle separation through iterative design of various separator geometries; and (3) model and integrate a magnetic separation system with the final electrostatic prototype to optimize particle size distribution (PSD) and enrich iron-aluminum minerals based on their magnetic properties. The methodology involved developing an empirical model for particle separation, utilizing a static time-stepping interaction framework to track the dynamics of charged particles, enabling predictions of separation efficiency. The model discretizes PSD into bins and tracks their motion utilizing electrostatic and magnetic parameters governed by the applied numerical equations. Simulations were calibrated and validated against experimental data which provided precise multimodal particle density functions (PDFs) and scrutinized how the distribution functions of the particles manifest as the electrostatic-magnetic field propagates. Results indicated significant influence of sorting mechanisms and control parameters, including varying feed rate (0.14-0.18 kg/h), inclination angles (10°-20°), electrical phase angles (90°-360°), and port lengths (10-50 cm) at different excitation frequencies (10-20 Hz). The electrostatic sweeping system stands out as the successful separator for effective separation (> 70%) achieving efficiencies of 88-90% for 40-50 µm particles at 30 Hz and a collection rate of 0.16 kg/h, while efficiencies for larger particles reach 80-90% at lower frequencies. Sensitivity analysis from magnetic separation demonstrated that increasing the feed rate decreases separation efficiency due to particle overcrowding, with optimal efficiency achieved at 125-150 g/min. Recovery rates for diamagnetic particles were approximately 90% for Highlands (310 rpm) and 60% for Mare (465 rpm) at specific speeds with varying angle of repose (30°-46°) presenting improved particle distribution and facilitating smooth settling of heavier particles while indicating higher speeds enhancing mixing but potentially causing turbulence and particle ejection. Increasing magnetic flux density from 0 to 2 T correlated with a decrease in cumulative mass percentages, denoting that stronger magnetic fields may hinder the separation process. Highlands simulants demonstrated greater separation efficiency at moderate magnetic field strengths, whereas Mare simulants performed better under lower densities. By establishing a robust framework for efficient moon mining, this research utilized computational modeling to offer scalable solution with a view to developing a beneficiation system and creating suitable feedstocks from mineral grains in lunar regolith to optimize the key performance indicators (KPIs) for enhanced separation purity.

Objectives with specific aims and possible outcomes:

Objective 1: Simulate particle trajectories in an electrostatic sieve to optimize control parameters for particle-size classification. This objective focuses on the development of a size-separation system that effectively categorizes a range of lunar regolith simulants. Computational modeling plays a key role in identifying the ideal operating parameters to achieve precise transportation and separation outcomes.

Objective 2: Model an electrostatic system to achieve efficient particle separation through iterative design and testing of various separator geometries. This involves designing an electrostatic separation system to enrich targeted minerals and validate its performance through experimental results under varying conditions, aiming for optimal separation efficiencies.

Objective 3: Develop and model a magnetic separator and integrate the final electrostatic system into complete beneficiation system that enhances the concentration and optimizes the grain size distribution of the regolith feedstock via simultaneous magnetic and electrostatic separation system. The final system aims to achieve >70 wt% enrichment of anorthite with a particle size range of 20-200 µm, while optimizing KPIs to support future ISRU activities on the Moon.

Project: LuSTR21 (Lunar Surface Technology Research 21)

Publication: (i) https://doi:10.1061/9780784485736.007;(ii) TBP; (iii) TBP

(i) Moinee, A. A.; Bachle, P. F.; Newport, K.; Smith, J.; Bayless, D.; Schonberg, W.; Han, D.; Rezaei, F. Electrostatic Sorting of Lunar Regolith Simulants for Sustainable Resource Utilization: Modeling and Characterization of Particle Size Distributions. In Earth and Space: Engineering for Extreme Environments, ASCE Library, 2024, 68–83. https://doi:10.1061/9780784485736.007

Biblipgraphy:

[1] Zhang, P.; Dai, W.; Niu, R.; Zhang, G.; Liu, G.; Liu, X.; Bo, Z.; Wang, Z.; Zheng, H.; Liu, C.; Yang, H.; Bai, Y.; Zhang, Y.; Yan, D.; Zhou, K.; Gao, M. Overview of the Lunar In Situ Resource Utilization Techniques for Future Lunar Missions. Sp. Sci. & Technol. 2024, 3, 37. https://doi.org/10.34133/space.0037

[2] Sacksteder, Kurt R.; Sanders, Gerald B. In-situ resource utilization for lunar and mars exploration. AIAA 2007-345. AIAA Aerospace Sciences Meeting and Exhibit. 2007. doi:10.2514/6.2007-345. ISBN 978-1-62410-012-3

[3] Sanders, Gerald B.; Larson, William E. Integration of In-Situ Resource Utilization into lunar/Mars exploration through field analogs. Advances in Space Research. 2011, 47 (1), 20-29. doi.org/10.1016/j.asr.2010.08.020

[4] CSIC Scientific Challenges: Towards 2030. ISRU. 2021, 13–41 www.itefi.csic.es/sites/default/files/publicaciones/v12c1-in-situ-resources-utilization.pdf

[5] Franke, M. F. Development of a Testbed for the Beneficiation of Lunar Regolith Concentrating an Ilmenite-Rich Feedstock for In-Situ Oxygen Production on the Moon. Master’s Thesis, German Aerospace Center, https://elib.dlr.de/185548/1/MA_SpaceEngineering_Franke_3218889_Digital2.pdf

[6] Rasera, J. N.; Cilliers, J. J.; Lamamy, J. A.; Hadler, K. The Beneficiation of Lunar Regolith for Space Resource Utilisation: A Review. Planet. Space Sci. 2020, 186, 104879. https://doi.org/10.1016/j.pss.2020.104879

[7] Moinee, A. A.; Bachle, P. F.; Newport, K.; Smith, J.; Bayless, D.; Schonberg, W.; Han, D.; Rezaei, F. Electrostatic Sorting of Lunar Regolith Simulants for Sustainable Resource Utilization: Modeling and Characterization of Particle Size Distributions. In Earth and Space: Engineering for Extreme Environments, ASCE Library, 2024, 68–83. https://doi:10.1061/9780784485736.007

[8] Mckay, D. S.; Heiken, G.; Basu, A.; Blanford, G.; Simon, S.; Reedy, R.; French, B. M.; Papike, J. The Lunar Regolith – Lunar Sourcebook, Lunar and Planetary Institute 1991. Available at https://www.lpi.usra.edu/publications/books/lunar_sourcebook/pdf/Chapter07.pdf

[9] Taylor, L. A.; Schmitt, H. H.; Carrier, W. D.; Nakagawa, M. The Lunar Dust Problem: From Liability to Asset. A Collect. Tech. Pap. - 1st Sp. Explor. Conf. Contin. Voyag. Discov. 2005, 1 (February), 71–78. https://doi.org/10.2514/6.2005-2510

[10] Photo Journal, NASA Jet Propulsion Laboratory, California, USA. Available at: https://photojournal.jpl.nasa.gov/catalog/PIA00131

[11] Funsten, H. O.; Allegrini, F.; Bochsler, P. A.; Fuselier, S. A.; Gruntman, M.; Henderson, K.; Janzen, P. H.; Johnson, R. E.; Larsen, B. A.; Lawrence, D. J.; McComas, D. J.; Möbius, E.; Reisenfeld, D. B.; Rodríguez, D.; Schwadron, N. A.; Wurz, P. Reflection of Solar Wind Hydrogen from the Lunar Surface. J. Geophys. Res. Planets 2013, 118 (2), 292–305. https://doi.org/10.1002/jgre.20055

[12] Carrier III, W. D.; Olhoeft, R.; Mendell, W. Physical Properties of The Lunar Surface – Lunar Sourcebook, Lunar and Planetary Institute 1991, https://www.lpi.usra.edu/publications/books/lunar_sourcebook/pdf/Chapter09.pdf

[13] Carrier, W. D. The Four Things You Need to Know about the GEOTECHNICAL PROPERTIES OF LUNAR SOIL; 2005. https://www.lpi.usra.edu/lunar/surface/carrier_lunar_soils.pdf

[14] Carrier, W. D. Particle Size Distribution of Lunar Soil. J. Geotech. Geoenvironmental Eng. 2003, 129 (10), 956–959. https://doi.org/10.1061/(asce)1090-0241(2003)129:10(956)

[15] Heiken, G. H.; Vaniman, D. T.; and French, B. M. Lunar sourcebook: a user's guide to the Moon 1991, Lunar and Planetary Institute, https://www.lpi.usra.edu/publications/books/lunar_sourcebook/pdf/LunarSourceBook.pdf

[16] Kulkarni, K.; Fabien Franke, M.; Jundullah Hanafi, M. I.; Gesing, T. M.; Zabel, P. Optimizing Lunar Regolith Beneficiation for Ilmenite Enrichment. Front. Sp. Technol. 2024, 4, 1–12. doi.org/10.3389/frspt.2023.1328341

[17] Wang, H.; Phillips, J. R.; Dove, A. R.; Elgohary, T. A. Investigating Particle-Particle Electrostatic Effects on Charged Lunar Dust Transport via Discrete Element Modeling. Adv. Sp. Res. 2022, 70 (10), 3231–3248. https://doi.org/10.1016/j.asr.2022.08.080

[18] Colwell, J. E.; Batiste, S.; Horányi, M.; Robertson, S.; Sture, S. Lunar Surface: Dust Dynamics and Regolith Mechanics. Rev. Geophys. 2007, 45 (2), 1–26. https://doi.org/10.1029/2005RG000184

[19] Knudsen, C. W., and Gibson, M. A. Apparatus for manufacture of oxygen from lunar ilmenite, United States Patent, US5536378A, 1996. https://patentimages.storage.googleapis.com/9c/d0/20/7c6f209ea6f2ed/US5536378.pdf

[20] Taylor, L. A., Pieters, C. M. and Britt, D. Evaluations of lunar regolith simulants, Planetary and Space Science. 2016, 126, pp. 1–7. doi: 10.1016/j.pss.2016.04.005

[21] Sibille, L., Carpenter, P., Schlageck, and French, R. A. Lunar regolith simulant materials: recommendations for standardization, production, and usage. Tech. rep., NASA Marshall Space Flight Center, NASA/TP-2006-214605. 2006. Available at https://ntrs.nasa.gov/search.jsp?R=20060051776

[22] Williams, R. J., MCkay, D. S., Giles, D., and Bunch, T. E. Mining and beneficiation of lunar ores, Space Resources and Space Settlements, NASA Technical Reports Server. 1979, 275-288. Available at https://ntrs.nasa.gov/citations/19790024070

[23] Stubbs, T. J.; Vondrak, R. R.; Farrell, W. M. A Dynamic Fountain Model for Lunar Dust. Adv. Sp. Res. 2006, 37 (1), 59–66. https://doi.org/10.1016/j.asr.2005.04.048

[24] Hartzell, C. M.; Scheeres, D. J. The Role of Cohesive Forces in Particle Launching on the Moon and Asteroids. Planet. Space Sci. 2011, 59 (14), 1758–1768. https://doi.org/10.1016/j.pss.2011.04.017

[25] Gupta, R.; Gidaspow, D.; Wasan, D. T. Electrostatic Separation of Powder Mixtures Based on the Work Functions of Its Constituents. Powder Technol. 1993, 75 (1), 79–87. Available at https://doi.org/10.1016/0032-5910(93)80027-8

[26] Bachle, P. F.; Smith, J.; Rezaei, F.; Bayless, D.; Schonberg, W.; Han, D. Beneficiation of Lunar Regolith Simulants through Electrostatic Sieving and Magnetic Separation. In AIAA SCITECH 2024 Forum; https://doi.org/10.2514/6.2024-2539

[27] Adachi, M.; Moroka, H.; Kawamoto, H.; Wakabayashi, S.; Hoshino, T. Particle-Size Sorting System of Lunar Regolith Using Electrostatic Traveling Wave. J. Electrostat. 2017, 89, 69–76. https://doi.org/https://doi.org/10.1016/j.elstat.2017.08.002

[28] Kobaka, J.; Katzer, J.; Seweryn, K. Magnetic Separation of Lunar Regolith as Its Beneficiation for Construction Effort on the Moon. Artif. Satell. 2023, 58 (S1), 203–213. https://doi.org/10.2478/arsa-2023-0023

[29] Runcorn, S. K. On the Interpretation of Lunar Magnetism. Phys. Earth Planet. Inter. 1975, 10 (4), 327–335. https://doi.org/10.1016/0031-9201(75)90059-X.

[30] Taylor, L. A.; Oder, R. R. Magnetic Beneficiation of Highland and Hi-Ti Mare Soils: Rock, Mineral, and Glassy Components. Eng. Constr. Oper. Sp. II 1990, 1, 143–152. https://www.semanticscholar.org/paper/Magnetic-Beneficiation-of-Highland-and-Hi-Ti-Mare-Taylor-Oder/391e5930c744c05d1f73e77e8fa360226609e213

[31] Berggren, M.; Zubrin, R.; Jonscher, P.; Kilgore, J. Lunar Soil Particle Separator. In 49th AIAA Aerospace Sciences Meeting including the New Horizons Forum and Aerospace Exposition; Aerospace Sciences Meetings; American Institute of Aeronautics and Astronautics, 2011. https://doi.org/doi:10.2514/6.2011-436

[32] Wang, Z.; Tian, D.; Ma, Z.; Zhao, C.; Liu, Y.; Liu, Y.; Ding, Y.; Shen, Z. An Electrostatic Lofting Model Based on Adhesion Separation Characteristics for Lunar Dust. Planet. Space Sci. 2020, 184, 104883. https://doi.org/10.1016/j.pss.2020.104883

[33] Stubbs, T. J.; Farrell, W. M.; Halekas, J. S.; Burchill, J. K.; Collier, M. R.; Zimmerman, M. I.; Vondrak, R. R.; Delory, G. T.; Pfaff, R. F. Dependence of Lunar Surface Charging on Solar Wind Plasma Conditions and Solar Irradiation. Planet. Space Sci. 2014, 90, 10–27. https://doi.org/10.1016/j.pss.2013.07.008

https://calendar.mst.edu/event/final-doctoral-defense-for-abdullah-al-moinee https://drive.google.com/file/d/1Kq3eJjQBE6RLxod5h5e_iIFWcehJ9OCI/view?usp=sharing

https://drive.google.com/file/d/1Kq3eJjQBE6RLxod5h5e_iIFWcehJ9OCI/view?usp=sharing

Committee Members

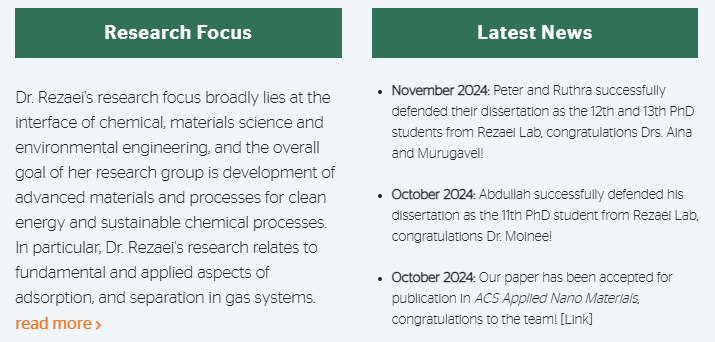

Friday 25 October 2024

|  |

Commencement:

https://www.flipsnack.com/missourisandt/missouri-s-t-digital-commencement-program/full-view.html

Doctoral (Ph.D.) Commencement Fall 2024 [12.13.24; 18:00], MO 65401, USA